We are committed to focusing and prioritizing your per requirement:

All project inspections are managed by a dedicated coordinator who focuses on each client.

All project inspections are witnessed or monitor by competent certificated inspector.

As a professional inspection service company, OPTM provides QA/QC support at different stages of a project.

To check in advance for compliance with client expectations and ensure good project development, in order to minimize or avoid additional cost risks due to subsequent on-site failures.

This reduces your risk in the procurement process.

OPTM Inspection services are provided by highly qualified and extremely competent technical inspectors, fully conversant with the International codes, industry standards, and product standards, qualified and certified for several processes.

We accept the client's entrustment to provide vendor evaluation and assessment, production surveillance, on-site inspection, container loading monitoring and other inspection services.

Parts of our inspectors certification as below:

AI, CWI/SCWI, CSWIP3.1/3.2, IWI, IWE, NDT, SSPC/NACE, CompEx, IRCA auditors,

Saudi Aramco Inspection approvals (QM01,02, QM03,04,05,06,07,08,09,12,14,15,30,35,41) and API inspector etc.

As your trusted expediting partner, OPTM provides effective assistance and coordination, working with every link in your supply chain to ensure that your orders are delivereded on time.

OPTM's expediting services include: office expediting, visiting expediting, resident supervision expediting, and production schedule expediting .

All expediting services are performed by our experienced professionals in close cooperation with you and the supplier, when deadlines are at risk.

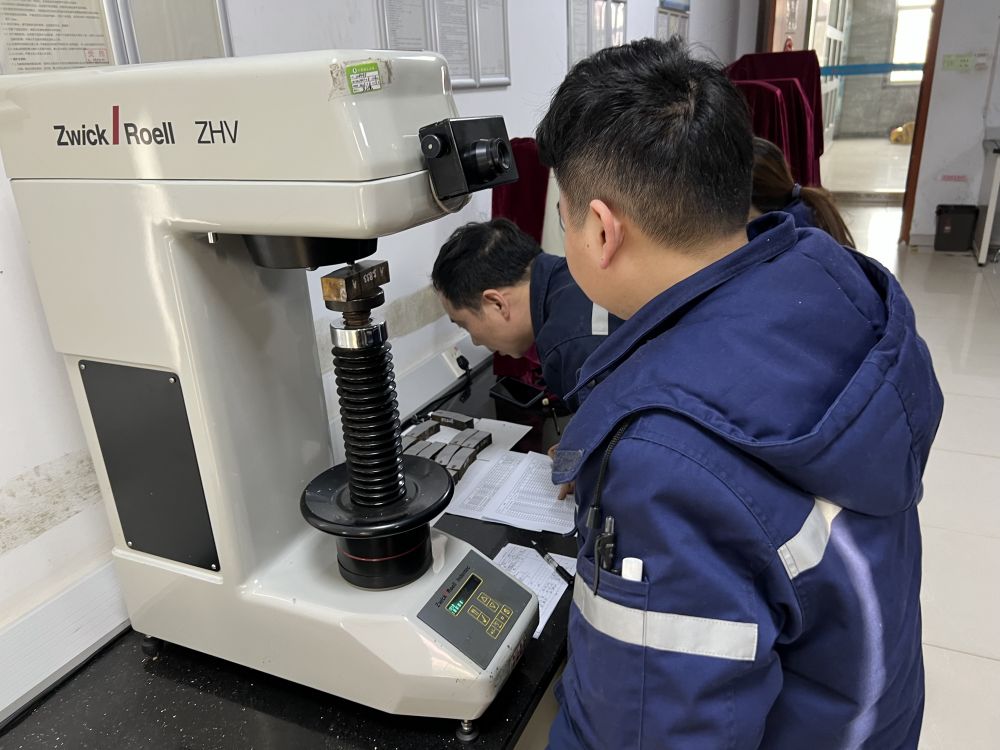

OPTM can cooperate with third-party laboratories to provide testing services for various materials and samples. Supervise laboratory inspection according to customer requirement.

OPTM can also help customers connect with long-term third-party laboratories to provide advanced testing equipment and technology to save customers overall costs.

OPTM offers world-class services in non-destructive testing (NDT) across a wide range of industries and verticals. We understand the processes involved throughout the entire product cycle, and undertake on-site testing, laboratory testing and factory testing assignments.

Our vast expertise and knowledge in NDT means we can select the right techniques and procedures, complemented by skilled personnel to carry out the testing, and provide you with necessary data to assist you in making informed decisions to to ensure total project success.

OPTM works with a variety of industries including oil and gas, petrochemical, refinery, chemical plant, power generation, heavy manufacturing, industrial and manufacturing. We focus on continuous improvement in our insights, comprehensive analysis, and professionalism to ensure that project is planned and executed perfectly to achieve timely completion.

Our global services can offer you a comprehensive range of NDT services, includes but is not limited to:

Penetrant Testing

● Magnetic Particle Testing

● Ultrasonic Thickness Measurement

● Ultrasonic Flaw Detection

● Radiographic Testing – X-ray, Gamma Ray

● Digital / Computer Radiographic Testing

● Boroscopy / Videoscopy Inspection

● Vacuum Box Leak Testing

● Helium Leak Detection Testing

● Infrared Thermography Testing

● Positive Material Identification

● Hardness measurement

● In-situ Metallography (REPLICA)

● Natural Frequency Testing

● Ferrite Measurement

● Holiday Testing

● Tube Inspection

● Phased Array UT (PAUT)

● Time of Flight Diffraction (TOFD)

● Tank Floor Mapping

● Long Range Ultrasonic Testing (LRUT)

● Short Range Ultrasonic Testing (SRUT)

● Pulsed Eddy Current Testing (PEC)

● Corrosion under insulation (CUI)

● Acoustic Emission Testing (AET)

● Acoustic Pulse Reflectometry Testing

● Alternating Current Field Measurement (ACFM)

● Automated Corrosion Mapping

● Reformer Tube Inspection

● Residual Stress Measurement

Magnetic Barkhausen Noise (MBN) method

OPTM third party audit services provide inspections at vendor's premises,expediting of the project equipment,vendor evaluation and assessment,vendor rating. At this stage, we provide our client with detailed information about the factory, such as production capacity, quality control capabilities and other important information.

OPTM has dedicated inspection personnels, with rich experience in auditing, can provide objective and reliable inspection according to your inspection requirements and product characteristics, and submit a formal inspection report to ensure that you have a detailed understanding of the supply capacity of the factory and quality assurance.

OPTM human resource services provide contracting secondment, permanent/direct recruitment, technical training,talent acquisition,staff secondment, maintenance excellence training,offshore recruitment, career industry training.

OPTM provides client with engineering and technical personnel, including engineering supervisors, construction managers, logistics personnel and quality NDT testing personnel.

OPTM offers a variety of training, including welding consulting and training, NDT personnel training, API training. According to the needs of client, we can also provide on-site training.